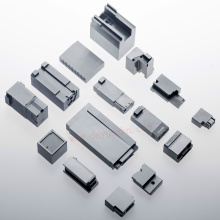

Fr-4 Machined Parts with High Strength

Basic Info

Model No.: PR-FR4-1

Product Description

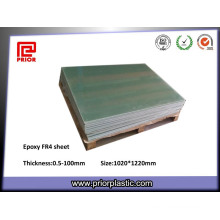

Model NO.: PR-FR4-1 Type: Solid Material: Fiberglass Maximum Voltage: 20KV~100KV Certification: SGS Brand: Prior Size: 1020*1220mm, 1220*2440mm Sample Availabitliy: Yes Trademark: PRIOR Origin: China Application: Insulators, Switch Baseplate, Transformer Chemistry: Inorganic Insulation Thermal Rating: E 120 Classification: Inorganic Insulation Material Color: Light Green Thickness: 0.5-100mm FOB Port: Shenzhen Small Order: Accepted Specification: SGS, RoHS HS Code: 3920999090 FR-4 machined parts with high strength

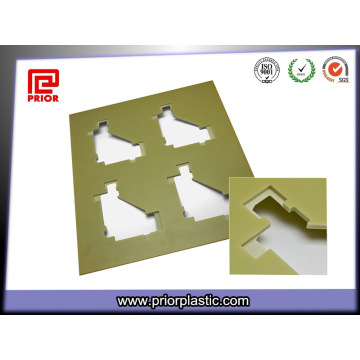

In plastic field, many suppliers know the material, but they know little about the machining. Some other suppliers know about the machining, but they don't know the material properties. In the two situations, problems happen frequently.

If you have same problem, come to PRIOR PLASTIC, we solve the problem for you perfectly. Experienced both in material and machining, customers are very glad to cooperate with us.

The machining process include below

1.Turning: For parts which have high surface requirement, wide-head cutters are better. When processing thin walled and soft material, cutters like knife are recommended.

2. Milling: When milling the surface, end-milling is more cost-effective than circular milling. For circular and forming cutter, it should have less than two cutter edges. In this case, the tolerance caused due to the edge vibration can be lowered to the minimum.

3. Sawing: Thin saws are usually used to saw thick parts to avoid the heating caused by friction. It would be better to use sharp and big sawblade.

4. Drilling: When drilling the solid materials, make sure to use sharp drill, otherwise the increasing pressure during drilling will cause material cracks.

The common document files accepted are : *.pdf/*.dwg/*.IGS/*.step/*.prt/*.sldprt Just send the drawings to us, we will handle the rest for you.

Technical Data Sheet

Contact us if you need more details on Fr-4 Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Epoxy Sheet、Fiber Glass Sheet. If these products fail to match your need, please contact us and we would like to provide relevant information.

In plastic field, many suppliers know the material, but they know little about the machining. Some other suppliers know about the machining, but they don't know the material properties. In the two situations, problems happen frequently.

If you have same problem, come to PRIOR PLASTIC, we solve the problem for you perfectly. Experienced both in material and machining, customers are very glad to cooperate with us.

The machining process include below

1.Turning: For parts which have high surface requirement, wide-head cutters are better. When processing thin walled and soft material, cutters like knife are recommended.

2. Milling: When milling the surface, end-milling is more cost-effective than circular milling. For circular and forming cutter, it should have less than two cutter edges. In this case, the tolerance caused due to the edge vibration can be lowered to the minimum.

3. Sawing: Thin saws are usually used to saw thick parts to avoid the heating caused by friction. It would be better to use sharp and big sawblade.

4. Drilling: When drilling the solid materials, make sure to use sharp drill, otherwise the increasing pressure during drilling will cause material cracks.

The common document files accepted are : *.pdf/*.dwg/*.IGS/*.step/*.prt/*.sldprt Just send the drawings to us, we will handle the rest for you.

Technical Data Sheet

| Technical Data | Method of Verification | Unit | 3240 |

| I.Physical Properties | |||

| Density | ISO 1183 | g/cm3 | 2.0~2.1 |

| Water absorption 24hrs | ISO 62 | % | 0.05~0.15 |

| III.Thermal Properties | |||

| Max. service temperature -Short term | ISO 75-2 | ºC | / |

| Max. service temperature - Long term | ISO 75-2 | ºC | 130~140 |

| Coefficient of Thermal Expansion-LW | ISO 11359 | m/K | / |

| Coefficient of Thermal Expansion-CW | ISO 11359 | m/K | / |

| Thermal Conductivity | ISO 11359 | W/(m·K) | 2.2~2.5 |

| Flammability | UL 94 | Class | V-1 |

| II.Mechanical Properties | |||

| Tensile strength at yield | ISO 527-2 | MPa | ≥220 |

| Tensile strength at break | ISO 527-2 | Mpa | / |

| Hardness Rockwell | DIN 53505 | 120-125 | |

| Izod impact strength | ISO 179 | kJ/m2 | ≥33 |

| Bending Strength | ISO 527-2 | Mpa | / |

| Flexural strength-LW | ISO 179 | Mpa | ≥314 |

| Flexural strength-CW | ISO 179 | Mpa | ≥216 |

| Adhesive Strength | ISO 179 | N | 5600 |

| Compression strength-LW | ISO 179 | Mpa | ≥350 |

| Compression strength-CW | ISO 179 | Mpa | ≥147 |

| IV.Electrical Properties | |||

| Volume resistively | IEC 60093 | Ohm (Ω) * cm | 1.3x1014 |

| Surface resisively | IEC 60093 | Ohm (Ω) | 3.5x1012 |

| Electric strength- LW | VDE 0303 | kV/mm | ≥14.2 |

| Breakdown Voltage-CW | VDE 0303 | kV | >34 |

| Relative dielectric coefficient | VDE 0303 | / | ≤4.7 |

| Dielectric Loss mudule | VDE 0303 | 50HZ | ≤0.04 |

| Arc resistance | VDE 0303 | S | / |

| NOTE: 1 g/cm3 = 1,000 kg/m3, 1 Mpa = 1 N/mm2, 1kV/mm = 1 MV/m | |||

Contact us if you need more details on Fr-4 Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Epoxy Sheet、Fiber Glass Sheet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Machined Parts

Premium Related Products

Other Products

Hot Products

PTFE machine conveyor beltNITTO DENKO PTFE High temperature Adhesive TapeNITTO PTFE Heat Resistant Adhesive Tapeheat insulation material ptfe sealing tapeFluorine resin impregnated glass fiber cloth Adhesive TapeHot sale cheap good quality adhesive white ptfe fiberglass fabricHigh intensity with long use waterproof insulation single-sided fabric tapeExcellent corrosion resistance pure virgin teflon ptfe sheetLow Price Guaranteed Quality alkali resistant fiberglass mesh tapeFactory sale various widely used Heat Resistant Brown Color PTFE FabricSubstantial High Quality Heavy duty non-stick reusable barbeque linerPromotional Various Durable Using PTFE Film/PTFE skived filmWholesale Customized Good Quality white virgin ptfe sheetFactory sale various widely used cheap ptfe rod 2mm diameterHot selling good reputation high quality high temperature 12 mm ptfe tubeMade In China Good Reputation fiberglass mesh alkali resistant